Compact and manoeuvrable, the self-propelled MVS BELMIX outperforms most of its competitors in terms of handling safety and performance. The self-propelled Belmix flawlessly combines agility in handling with a sturdy feeling, while still giving a comfortable ride even in the most difficult situations. The machine’s wide range of settings allows it to adapt to the needs of all sorts of farms.

- Heavy-duty, robust, vertical single-auger mixing system with interchangeable knives.

- 170 CV (IVECO) engine located at the front on the right

- Hydraulic circuit located behind the cabin with flexible piping.

- Side discharge door (optional second side discharge door).

- Leaf-spring suspension on the front and rear axle.

- Rubber discharge conveyor belt.

- Front-axle drive and steering.

- Front-axle service and emergency parking.

- Travel speed 25 km/h

- Front steering axle with 40º turning.

- Variable displacement pumps to operate the drive system and the heavy-duty mixer system.

- Heavy-duty series mixer piston motor (420 bar).

- Sides and bottom in ST52 steel.

- Spiral auger in ST52 steel.

- 2,000 mm long cutter with a 90 CV motor.

- Folding cabin door.

- Air suspension seat.

- Programmable scale.

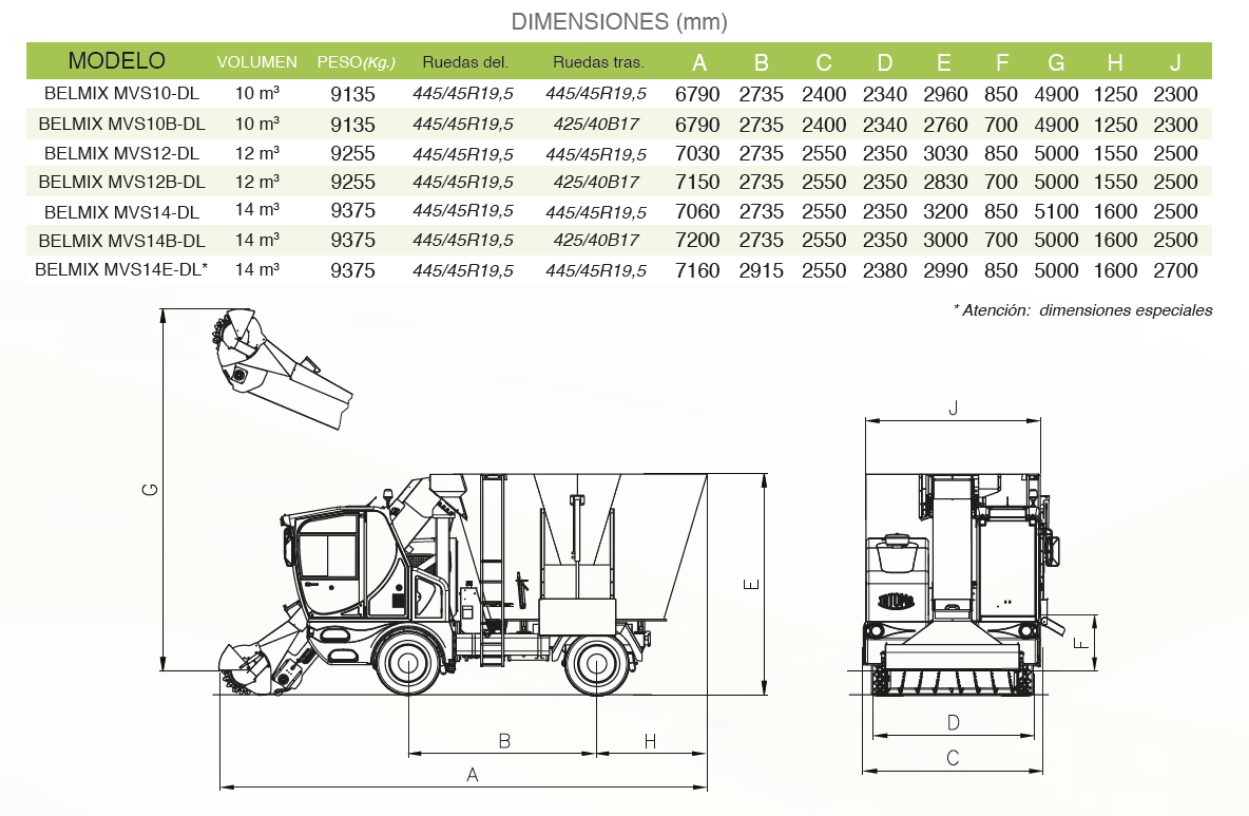

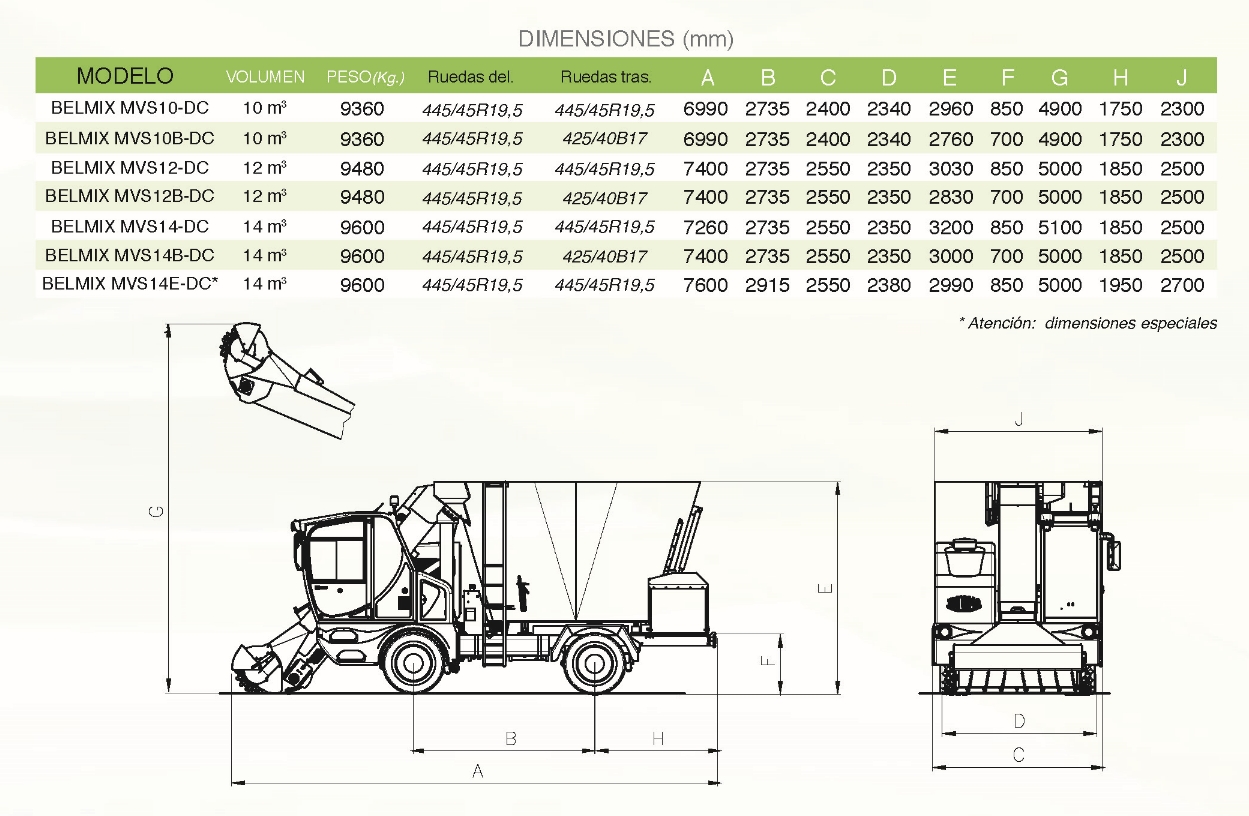

- Tyres ref. front 445.45-19.5 and rear 425/40 B17 (option 4X4 tyres 445/45-19.5).

- Manually operated cutter lowering adjustment from the cabin.

- Pressure switch to regulate the working pressure of the cutter.

- Mixer working pressure gauge.

- Mixer gear oil temperature gauge.

- Hydraulic oil temperature gauge.

- Low hydraulic oil level gauge.

- Breakdown lights switch.

- Extinguisher.

- Working lights.