Designed for maximum productivity, The GIGAMIX two auger vertical self-propelled mixer is a machine that can adapt to any work, regardless of how difficult the conditions on the farm are. With more than four decades of expertise in the production of mixing systems, TATOMA is able to guarantee the highest level of performance for its mixers, especially its self-propelled machines, which combine efficiency and durability to fulfil the needs of the most demanding farmer. The GIGAMIX model is well suited to the needs of a medium-sized farm and can prepare 200 to 250 mixing rations (depending on the model) in a matter of minutes.

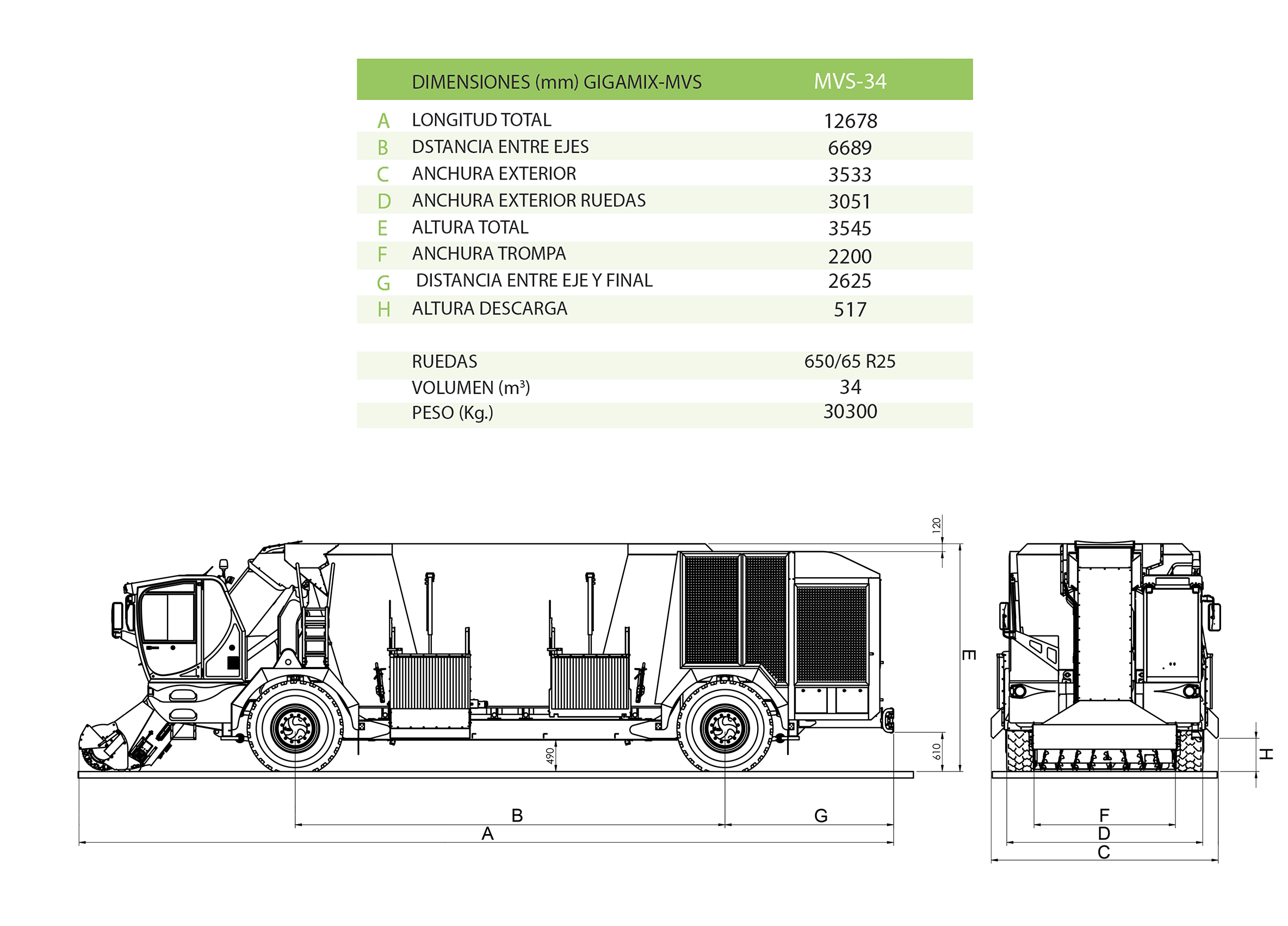

2-Auger vertical mixer rear motor “GIGAMIX” MVS 34

- 2 augers

- 205

- 6200x3330mm

Products / TMR Self-Propelled Mixers / TMR Vertical Self-Propelled / 2-Auger vertical mixer rear motor “GIGAMIX” MVS 34

Description of2-Auger vertical mixer rear motor “GIGAMIX” MVS 34

MÁS INFORMACIÓN

Si quieres saber más o pedir un presupuesto no dudes en consultarnos

MÁS INFORMACIÓN

Si quieres saber más o pedir un presupuesto no dudes en consultarnos

Model:

MVS-34 “GIGAMIX” 4WD-4WS

Engine:

Engine VOLVO TAD 1384 VE – 375 KW (510 CV) ASP 24V + KIT Low Temperatures (T5)

Unloading:

3 UNLOADING DOORS

Weighscale:

Electronic weighscale LABEL I FEED GOOD L (8 Cells D63 LABEL)

Travel speed:

2 speeds 0 to 12 and 0 to 35 Km/h

Tyres FRONT/REAR:

650/65 R25 MICHELIN XAD 65-1 SUPER E3T TL 180B

Traction:

On all 4 wheels

Steering:

On all 4 wheels:

Brake:

Service on all 4 wheels. Parking and negative-type emergency.

Suspension:

Hydraulic suspension arms FRONT and REAR (self-levelling and auto compensated)

Mixer:

2 Speed

Tub:

Tub volume 33,7

Cutter:

Width:

2200 INOX – Pitch 250-2M

Power (CV):

180 CV (2×500)

400 rpm

INOX drum e=5 Diameter 440. Outside diameter 650. Auger 70×10.

Loading belt:

Rubber band width 800. Adjustable speed 0-450 rpm. 1 Cushion lift cylinder . Upload speed 10 sec. Cutting height 6300 (centre). Band anti-slipping sensor.

Air conditioning:

Heating with diesel burner and hydraulic compressor air conditioning.

Accessories: Signalling for driving around the farm.

KIT 4 Rear Cameras + TFT Colour 7″ + 2 Cables 20 m (mix and reverse gear)

CLEANFIX reversible fan

420×200 heated, electrically adjustable mirrors

24 VDC (x2)

Low temperature kit for engine (pre-heating fuel filter and water resistance, motor 220 VAC) and hydraulic oil (2 resistances 220 VAC).

24VCC Automatic Centralized Lubrication

LED work lights (4 front, 2 side and 2 rear)

Limitations:

Maximum height 3600. Maximum width 3250. Tank-motor distance > 400 mm.

Observations:

Multifunction joystick to control travel mode, loading and unloading. Digital screen to visualize all machine and engine parameters. COBO steering column and electronic side console attached to the seat. Grammer seat MAXIMUM 24 VDC. Cutter, 2 pushbuttons and potentiometer.

Features:

Travel speed 35 km/h with 22 tons and 25 km/h with 36 tons. 25% slope when loaded possible. Internal turning radius of 4 m. Minimum mixing capacity 11500 kg. Assess components at 1600 engine rpm.

Requirements: 500 CV Motor to work at 1600-1700 rpm. Alternator > 140 A. 24 VDC installation. Batteries in sliding drawer, Cabin with anti-corrosion treatment. Visibility 110 degrees. Diesel tank of 500 L INOX.